Waste Plastic Pyrolysis Plant

5500000.00 INR/Unit

Product Details:

- Type Waste Plastic Pyrolysis Plant

- Voltage 380 V Volt (v)

- Power 15100k Watt (w)

- Weight (kg) 300015000 Kilograms (kg)

- Dimension (L*W*H) 6 3 3 Meter (m)

- Color Industrial Grey

- Warranty 1224 Months

- Click to View more

X

Waste Plastic Pyrolysis Plant Price And Quantity

- 5500000.00 INR/Unit

- 1 , , Unit

Waste Plastic Pyrolysis Plant Product Specifications

- 380 V Volt (v)

- Waste Plastic Pyrolysis Plant

- 6 3 3 Meter (m)

- Industrial Grey

- 1224 Months

- 15100k Watt (w)

- 300015000 Kilograms (kg)

Waste Plastic Pyrolysis Plant Trade Information

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Days

- All India

Product Description

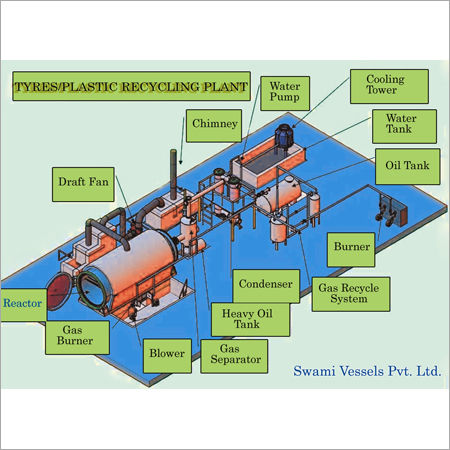

We are amongst the leading name in the industry which is engaged in manufacturing and supplying an extensive array of Pyrolysis Plant in the competitive market. Manufactured with superior quality raw materials, these plants confirm to the laid industry quality standards. Extensively used in different industries for converting all waste into usable fuels, this Pyrolysis Plant is widely known in the market for their high efficiency and low maintenance.

Special Features:

- Durability

- Easy installation

- Robust construction

- Long functional life

- Excellent performance

- Easy & Safe operation

- High operational fluency

Efficient Plastic Recycling Solution

This pyrolysis plant is designed to transform waste plastic into reusable fuel through a thermal decomposition process, offering a sustainable solution to plastic pollution for industries across India and globally. The high-powered system and sturdy construction allow for consistent outputs under various working conditions. With warranty coverage up to 24 months and comprehensive after-sales support, it is a dependable long-term investment.

Advanced Features and Build Quality

Equipped with a powerful 15100 kW motor and weighing up to 15,000 kg, the plant ensures stable operations. The standardized dimensions enable straightforward installation in both large and medium-scale recycling facilities. The grey industrial finish enhances corrosion resistance, while the 380V input supports heavy-duty industrial power requirements.

FAQs of Waste Plastic Pyrolysis Plant:

Q: How does the Waste Plastic Pyrolysis Plant convert plastic waste into fuel?

A: The plant uses pyrolysis, a process that heats waste plastics in the absence of oxygen, breaking them down into oil, gas, and residue. The resulting oil can be utilized as an alternative fuel, while the gas is often recycled within the system to improve efficiency.Q: What types of plastic can be processed in this pyrolysis plant?

A: This plant is capable of processing a wide variety of waste plastics, including polyethylene, polypropylene, and polystyrene, which are common in packaging and consumer goods. Proper sorting and pre-treatment may be required for optimal results.Q: When should maintenance and servicing be performed on the plant?

A: It is recommended to follow the maintenance schedule detailed in the user manual, with general servicing every 6 months and thorough inspections annually. Regular maintenance ensures smooth operation and longevity, especially within the 1224 month warranty period.Q: Where can this pyrolysis plant be installed and operated?

A: The unit can be installed in industrial zones and recycling facilities with appropriate space and a compatible 380V power supply. Its compact 6 3 3 meter dimensions facilitate flexible placement in a variety of factory layouts.Q: What is the usage process for operating the plant safely?

A: Operators should load sorted plastic wastes into the reactor, initiate the automated pyrolysis cycle, and monitor temperature and pressure through control panels. Detailed operational procedures and safety protocols are provided by the manufacturer to ensure safe usage.Q: What are the main benefits of using this waste plastic pyrolysis plant?

A: The plant offers a sustainable way to reduce plastic waste by turning it into valuable fuels. It promotes environmental protection, supports resource recovery, and reduces dependency on conventional energy sources. Additionally, its robust build and warranty provide operational peace of mind.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email